How To Make Plastisol Screen Print Transfers

In the video print expert Colin Huggins is printing a one-color heat transfer. The first step youre going to do is run the transfer paper through a conveyor dryer.

Plastisol Heat Transfers Screen Printing Youtube

FM uses screen printing methods and materials to print your images on transfer paper.

How to make plastisol screen print transfers. After printing the design onto paper and curing it with a flash dryer the adhesive powder is applied. In this video Ryan Moor takes you through all the steps from start to finish on how to accomplish. Figure 1 In simple terms a screen printed heat transfer is simply plastisol ink that is printed on a special release paper first and then partially cured in standard T-Shirt dryer flash unit and even under a partially closed heat transfer.

Make one screen for each color. Plastisol heat transfers are the reverse image of a screen print put down on specialized transfer paper. This powder helps the ink stick to the garment when its time for heat pressing.

Custom plastisol transfers use a special transfer paper which is printed as spot color inks as well as CMYK aka four color process inks such as Aqua Color HD formula. After the final color is laid down an adhesive powder is sprinkled on the wet ink. Without it your transfer would not stick very well or durability would suffer.

How to Make Plastisol Heat Transfers THE TRANSFER PAPER. Create a thicker ink buildup on the transfer paper so it. Heat Transfers Print your own apparel using our screen printed or digital transfers.

Then using the print and cut feature with your cutting machine you cut around the outside of the image. A screen print transfer also known as a plastisol transfer is an image which has been screen printed onto release paper. This has to be by far one of our most requested videos yet.

Make a printout of the areas that are the first color and use that to make a screen. Plastisol transfer inks can be custom mixed to match a specific pantone ink color however the color matching may look different on. Heat press set to 330 degrees.

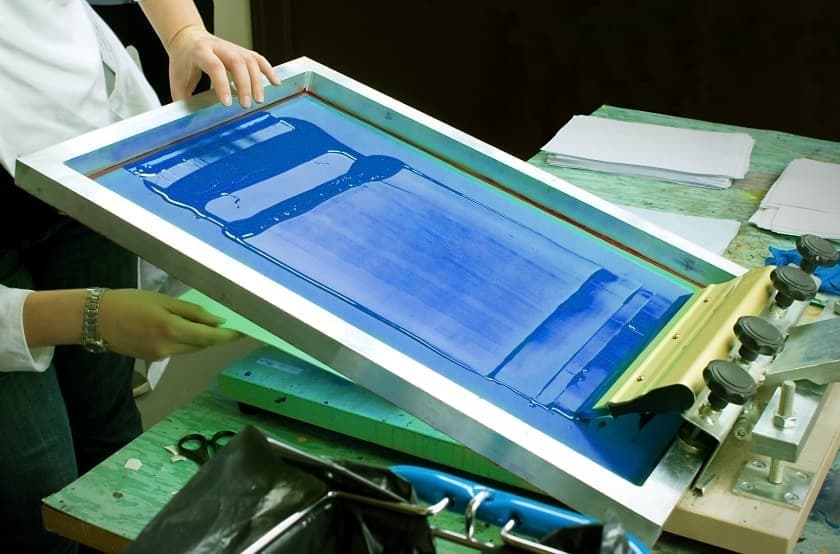

You need to set a standard off-contact of 116 and ensure this off-contact is consistent throughout the screen. Prepping Screen Print Transfers Use the round side of the scoop coater in order to deposit a thicker layer of emulsion onto your screen. Plastisol Ink Screen Print Transfer this can be applied to any combination of polyestercotton including 100 cotton.

And using the same traditional screen printing process printers use plastisol ink to print on a specialized heat transfer paper. The adhesive powder is the key to plastisol heat transfers. Set your heat press to 400 degrees.

Create a stencil. SCREEN PRINTING THE TRANSFER. Heat transfers can provide the same look and feel as traditional screen printing.

Change the screen to the one for the second color and apply that color. The ink on the paper is partially cured and then when its ready to be placed on a substrate the paper is placed facedown against the material and heated to around 400 degrees. Use our artwork or yours.

If you are printing only a few transfers you can use a small amount of spray adhesive to hold the transfer in place. You can choose from several stock ink colors without incurring any extra charges for custom ink mixing. Apply the color with the first screen and then let it dry.

Coat the outside of the screen and then the inside of the second screen with a 11 coating method. Everything you need to make plastisol heat transfershttpbitly3pQ84TMGrab The Hat Heat Press. Screen printing a heat transfer is pretty straightforward.

Once you have chosen your design you can print it through an ordinary inkjet printer onto the inkjet transfer paper. Stock Transfers Pre-printed designs in stock and ready to ship same day when ordered by 3 PM ET. Set your heat press to 400 degrees.

There are a number of Plastisol inks available. How to Make Plastisol Transfers Step 1. You can sketch it out with pencil and paper or create the image using a.

This article is specifically about making screen printed transfers. Instead of printing on fabric they will print on the hot peel paper. Choose or create the design you want.

Plastisol ink comes in tubs of varying sizes. Use our artwork or yours. Your printed graphics are then shipped right to your door so that you can press them onto your t-shirt or other product in just 7seconds.

Place sheets of white copy paper or parchment paper inside your shirt to prevent bleed through. No hassle no mess. Heat transfers can provide the same look and feel as traditional screen printing.

Plastisol Transfers Uk Custom Made 48 Hour Despatch

How To Make Screen Print Transfers Exile Technologies

Unlocking The Secrets To Plastisol Heat Transfers Youtube

Screen Printing Plastisol Heat Transfers

How To Make Plastisol Heat Transfers By Screenprinting Com

3 Tips To Help You Print Successful Plastisol Transfers Youtube

How To Make Screen Print Transfers Exile Technologies

Simple Guide To Screen Printing Plastisol Transfers Siss Ltd

Custom Plastisol Transfers Of Your Graphic Designs

How To Screen Print Plastisol Heat Transfers

Beginner S Guide To Screen Printed Transfers Youtube

Screen Print Your Own Heat Transfers Lawson Screen Digital

How To Use Plastisol Heat Transfers To Print T Shirts T Shirt Printer School

Plastisol Heat Transfer Durability And Longevity Howard Custom Transfers Inc Quality Custom Heat Transfers

Screen Printing Plastisol Heat Transfers

Beginners Guide To Screen Print Transfers From Transfer Express Youtube

Screen Printing Plastisol Transfers Youtube

How To Screen Print Printing Two Color Plastisol Heat Transfer Sheets Youtube

Post a Comment for "How To Make Plastisol Screen Print Transfers"